Reliable, High-Quality Metal

Fabrication Services

at a Reasonable Price

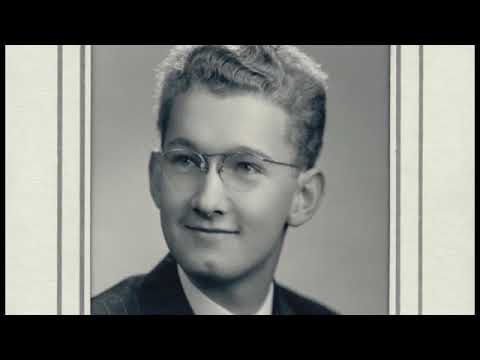

About

Styberg Engineering

Styberg Engineering has been a trusted contract manufacturer of custom metal fabrication parts, assemblies, and prototypes since 1927. As a home-grown community success story, we are proud to have worked our way from two people in a garage to a Racine, Wisconsin, mainstay by serving each customer as a unique and important part of our business. Today we deliver for a wide range of Original Equipment Manufacturers with 150 skilled employees in a fully equipped facility of 175,000 square feet. We specialize in custom fabrication of medium- to heavy-gauge metal components.

Fair Pricing, Dependable Quality, and Great Service

These are the most important reasons for customers to contract with Styberg Engineering. These are the criteria that we are judged on, and how we are compared to our competitors.

Leading Contract Manufacturer

We maintain a list of qualifications that can be used for all customers. This allows Styberg to produce whatever a customer needs to have manufactured. While there are many companies in competition with us, we feel our qualifications and products give Styberg an edge over other competitors.

Our State-of-the-art Capabilities Include:

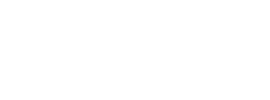

Fabrication

85 years of diverse experience combined with a full range of capabilities, enables us to become your one top shop for metal fabrication needs.

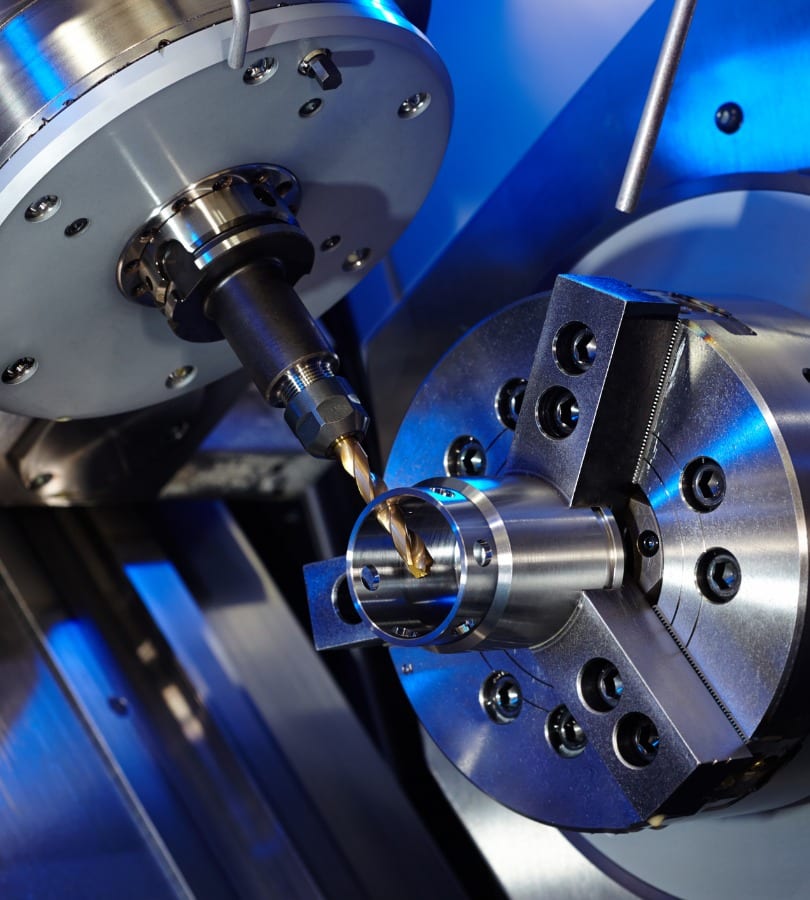

CNC Machining

From simple to the most challenging projects with odd-shaped requirements, we deliver.

Welding

As a NADCAP aerospace-certified welding company, we are qualified and capable of handling your simple to complex needs.

Metal Straightening & Flattening

We straighten steel, including stainless steel, with tight tolerances from 6” to 48” wide.

Heat Treating

Air- and oil-quenching processes mitigate shape deformation.

Spline Cutting & Custom Gear Fabrication

Our “Grob” process produces the most accurate form with greater depth and less weight than alternative processes.

Precision Metal Stamping

We can manufacture your most complex precision metal stampings from deep draws to metal forming.

Metal Surface Finishing & Grinding

We have equipment capable of maintaining multiple finishes including certain micro patterns such as “X”, “R”, and “C” that hold a maximum finish but also a minimum and maximum on the same part.

Why

Styberg Engineering?

Styberg Engineering delivers the highest quality product with a healthy dose of service.

With a complete line of metalworking machines and processes, Styberg can produce difficult components that require many diverse process operations. We provide our clients with a variety of benefits including:

- 1

All Services Performed Under One Roof

- 2

Complex Designs to Reduce Operations

- 3

Concurrent Engineering

- 4

Cost Reduction Through Process

- 5

Great Customer Service

- 6

Pre-production Prototyping

- 7

Equipment & Facilities